MIL-DTL-10057J

4.5 Testing. Unless otherwise specified herein, the following test shall be performed using

MIL-STD-1916.

4.5.1 Moisture content. Major defect.

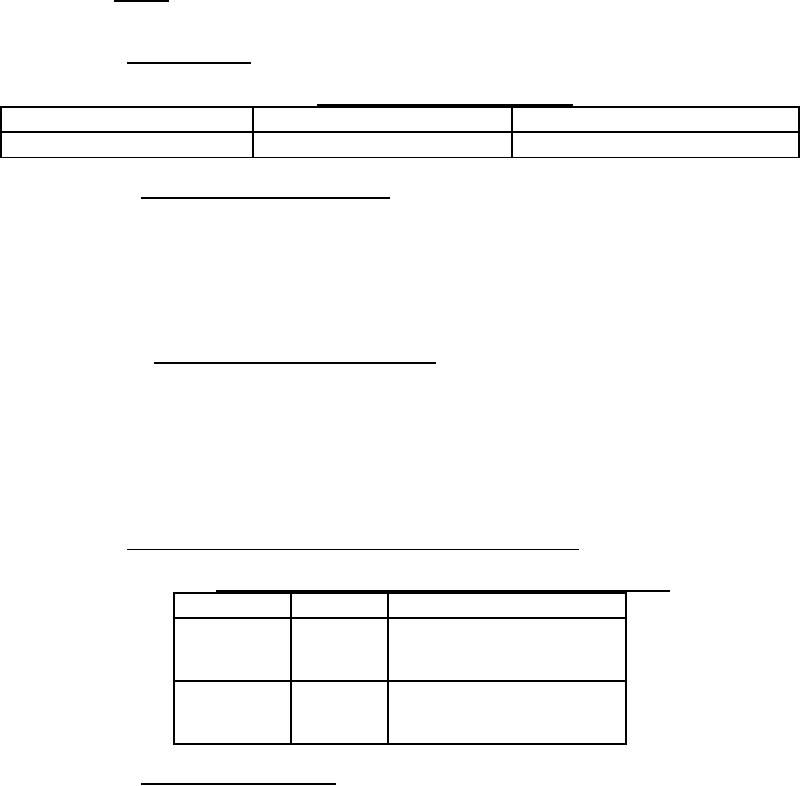

TABLE III. Major defects for moisture content.

Drawing

Material

Inspection Method Paragraph

Flash composition

12972326 or 13019989

4.7.1.1

4.5.1.1 Material samples moisture content. For verification, one sample of each material as

representative of eight (8) hours of production of simulators shall be selected and subject to test.

Composite samples shall not be used. If the moisture content of the sample exceeds the requirement,

that quantity or sub-lot of material represented by the sample shall not be used in production. If the

quantity of material or sub-lot with excessive moisture has been used in loading and packing, the

remaining unloaded and unpacked material shall not be used in production, and the loaded and

packed simulators shall be rejected.

4.5.1.1.1 Simulator ingredients moisture content. A sample of sufficient size (see paragraph

4.7.1.1) from each lot of each ingredient at the time of inserting the ingredient to the simulator for

determination of moisture content shall be selected. Controls shall be provided so that the moisture

content is maintained under constant temperature and humidity by a graphic recorder up to and at the

time of sealing and blending the charge in the simulators. If the sample fails to meet the

requirements, or if the simulators have been loaded with ingredients containing excessive moisture,

the remainder of the ingredient lot shall not be used in further production, and the lot of loaded

simulators shall be rejected.

4.5.2 Determination of granulation and composition of flash powder Major defect.

TABLE IV. Major defects for granulation and composition of flash powder.

Drawing

Material

Inspection Method Paragraph

12972326

Composition

or

4.7.2.2

13019989

12972326

Granulation

or

4.7.2.1

13019989

4.5.2.1 Flash composition samples. Adequate controls to insure that the flash composition

complies with the requirements shall be provided. Test for verification at least, one sample of the

composition of sufficient size (see paragraph 4.7.2) as representative of each eight (8) hours

production of simulators shall be provided. A composite sample shall not be used. If the sample fails

to meet the requirements for granulation or composition, or if the simulator has been loaded and

packed with non-conforming composition, the remaining unloaded composition shall not be used in

production and the lot of loaded simulators shall be rejected.

22

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business