MIL-DTL-20517J (AR)

4.4 Examination.

4.4.1 Chemical Sampling. Representative samples shall be tested in accordance

with ASTM E 300 procedure for solids.

4.4.2 Moisture determination. Moisture determinations shall be performed on the

components specified in Table III. Adequate controls shall be provided to assure that the

requirements are met. For verification, one sample of each material from each eight (8)

hours of production shall be selected, and subjected to test. A composite sample shall not

be used. If the moisture content of the sample exceeds the requirement, that quantity or

sub-lot of material represented by the sample shall not be used in production. If the

quantity of material or sub-lot with excessive moisture has been used in loading and

packing, the remaining unloaded and unpacked material shall not be used in production,

and the loaded and packed simulators shall be rejected. Test shall be performed as

specified in 4.5.1.

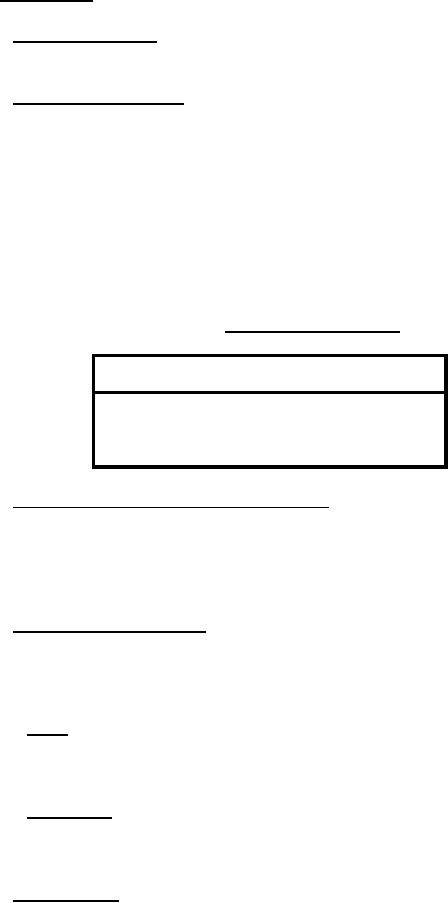

TABLE III. Moisture Determination.

Requirement

Test Method

Components

Paragraph

Paragraph

Black powder

3.2.1

4.5.1.2

Flash powder

3.2.2

4.5.1.1

Felt and Chipboard

3.2.4 - 3.2.6

4.5.1.3

4.4.3 Determination of flash powder composition. A sample of flash powder,

drawing 8848485, of not less than 5 grams shall be selected from each batch for test in

accordance with 4.5.2, using the procedure given in ASTM E300 for solids. If the sample

fails to comply with the requirement specified, the batch shall be rejected. Failure of a

batch shall be considered a major defect.

4.4.4 Compressive tube strength. Twenty six (26) tubes total from each lot shall

be tested in axial and diametrical directions to ensure the tube shall not interfere with the

rupture of the charge case assembly in functioning. Failure to comply with requirements

on drawing 8848484 shall be considered a major defect.

4.4.4.1 Axial. Thirteen (13) tubes shall be selected randomly from each lot for

test. If one or more tubes fail to comply with the requirement, the lot shall be rejected.

The test shall be performed as specified in 4.5.3.1. (Destructive test)

4.4.4.2 Diametrical. Thirteen (13) Tubes shall be selected randomly from each lot

for test. If one or more tubes fail to comply with the requirement, the lot shall be rejected.

The test shall be performed as specified in 4.5.3.2. (Destructive test)

4.4.5 Fragmentation. Twenty (20) loaded charge case assemblies shall be selected

from each lot and subjected to static functioning in accordance with the method specified

26

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business