MIL-F-81738 (AS)

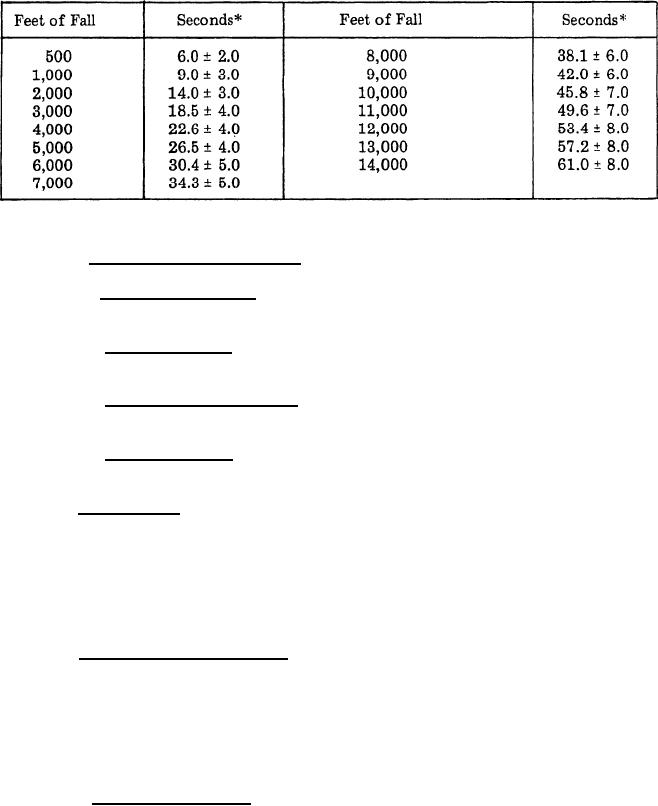

TABLE II

FOR FLIGHT TEST EJECTION DELAY TIMES

*Delay times for ejection at 4200 ± 500 MSL.

3.3.2 Durability and environmental.

3.3.2.1 Forty (40) foot drop. The flare shall withstand forty (40) foot drop with-

out exploding, burning or ejecting.

3.3.2.2 Aircraft vibration. The flare shall withstand aircraft vibration without

exploding, burning or ejecting.

3.3.2.3 Temperature and humidity. The flare shall withstand temperature and

humidity without exploding, burning or ejecting.

3.3.2.4 Low temperature. The flare shall be conditioned at a temperature of

-65°F ± 5° for a minimum period of 24 hours without exploding, burning or ejecting.

3.4 Workmanship. The product, in all stages of production, shall be processed

under such inspection control as to assure uniformity in quality. All components shall

be free of chips, dirt, grit, or other foreign material. The cleaning methods used shall

not be injurious to any of the parts nor shall any of the parts be contaminated by the

cleaning agents employed.

4.

QUALITY ASSURANCE PROVISIONS

4.1 Responsibility for inspection. Unless otherwise specified in the contractor

purchase order, the supplier is responsible for the performance of all inspection require-

ments as specified herein. Except as otherwise specified, the supplier may utilize his

own facilities or any commercial laboratory acceptable to the Government. The

Government reserves the right to perform any of the inspections set forth in the

specification, where such inspections are deemed necessary to assure supplies and ser-

vices conform to prescribed requirements.

4.1.1 Preproduction sample. The contractor shall deliver a sample of 144 flares

and 50 candle assemblies to the destination specified (see 6.2), for examination, testing,

6

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business